NO MATTER WHAT PROCESS COMBINATION IN THE END,

THERE IS ALWAYS A PRODUCT READY FOR INSTALLATION

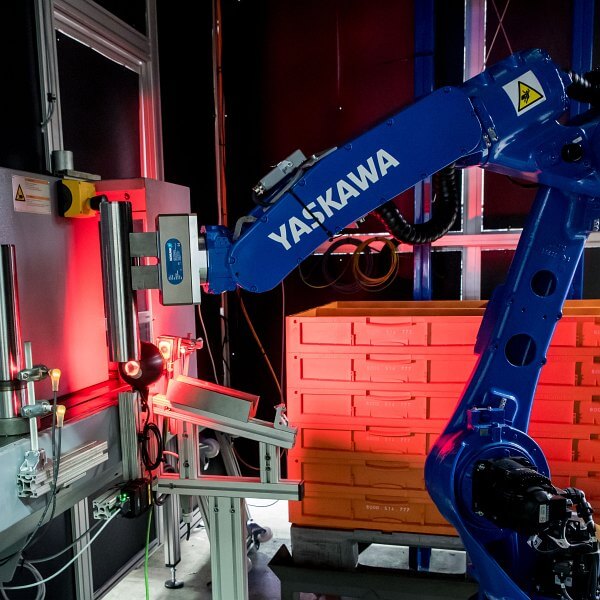

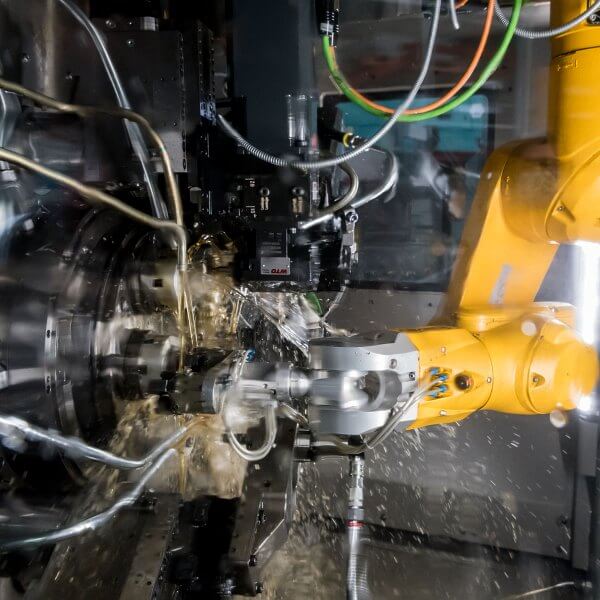

We use sophisticated processes and state-of-the-art technologies, and combine both aspects. Therefore, we expand our project-based and future-oriented portfolio to meet your requirements. Our strengths are dynamic, pro-active, and mandatory project implementations from process layout to sampling. With a 5,500 m² of production area and 2,760 m² of storage and logistical space available, there is always room for new ideas.

- Multi-spindle automatic lathes on bars (CNC and mechanically controlled)

- Multi-spindle turning on lathe chucks (CNC)

- Single-spindle turning on bars (CNC)

- Single-spindle turning on lathe chucks (CNC – vertically and horizontally)

- Rotary milling and drilling operations from bar (CNC and mechanically controlled)

- Rotary milling and drilling operations on lathe chucks (CNC and mechanically controlled)

- Centerless grinding

- Threads

- Spline rolling machine (CNC)

- Assembly technology fully-automated/ semi-automated (screw, rivet, press)

- Laser welding, laser marking

THE TURNED PART – ONE TERM AND TONS OF VARIATIONS

Our product portfolio is constantly growing – armature shafts, stop sleeves, connecting bolts, drive shafts, fittings, housings, threaded bushings, threaded inserts, sliding bolts, banjo bolts, coupling bolts, bearing bolts, steering bolts, magnet armatures, magnet housings, magnet cores, pole cores, knurled pins, ring fittings, tube nuts, rotor shafts, hose connecting pieces, screw sockets, locking bushing, connecting pieces, screw plugs, intermediate pieces.

Your product will be processed from

- bar turning parts with a diameter range from 6mm to 65mm, or as

- chuck parts up to a 200mm rotating diameter,

or in any common commodity and in any shapes.

“We may not be able to fulfill every task,

but we never categorically rule anything out”

Therefore, this is our approach in dealing with customer projects / customer issues

Our ever growing know-how as well as our creativity are the basis for any feasibility study and offer.

Our strengths are dynamic, pro-active, and mandatory project implementations from process layout to sampling.

Our product portfolio is constantly growing – armature shafts, stop sleeves, connecting bolts, drive shafts, fittings, housings, threaded bushings, threaded inserts, sliding bolts, banjo bolts, coupling bolts, bearing bolts, steering bolts, magnet armatures, magnet housings, magnet cores, pole cores, knurled pins, ring fittings, tube nuts, rotor shafts, hose connecting pieces, screw sockets, locking bushing, connecting pieces, screw plugs, intermediate pieces.

Your product will be processed from

- bar turning parts with a diameter range from 6mm to 65mm, or as

- chuck parts up to a 200mm rotating diameter,

or in any common commodity and in any shapes.

“We may not be able to fulfill every task,

but we never categorically rule anything out”

Therefore, this is our approach in dealing with customer projects / customer issues

Our ever growing know-how as well as our creativity are the basis for any feasibility study and offer.

Our strengths are dynamic, pro-active, and mandatory project implementations from process layout to sampling.

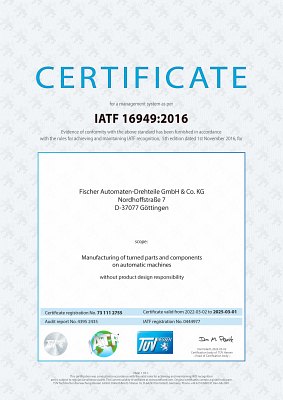

QUALITY IN ANY ASPECT - THIS IS OUR BUSINESS

The certified and integrated quality, environmental, and energy management system supports our employees in their daily commitment to “Fischer quality” in product, performance, and sustainability.

Integrated QM software solutions as well as special quality tools enable us to comply with any customer’s requirements”.

Through constant monitoring and the ability to adapt to specific customer requirements, the system is continuously growing.

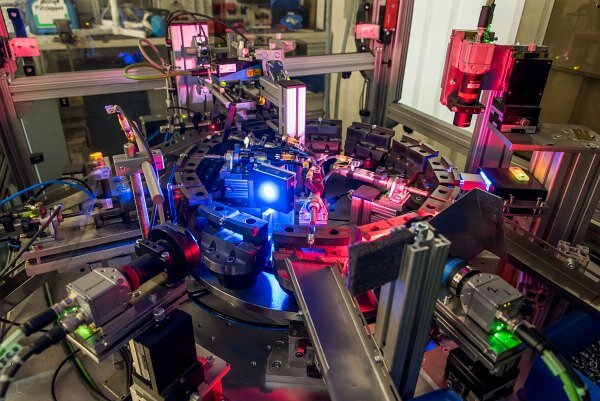

IF THERE IS NO FEASIBLE MEASUREMENT, THERE IS NO FEASIBLE PRODUCTION

The extensive testing and measuring devices are an important feature for the continuous monitoring of our production processes,

Standard devices and individual measuring devices are subject to systematic control of inspection, measuring and monitoring devices. They are calibrated, both internally and externally, to perform highly accurate inspection processes.

To implement dynamic and flexible inspection processes, there is a wide range of gauges as well as standard measuring devices.

Fischer Automaten-Drehteile – fully automated inspection machine (100% visual/tactile inspection).

We also use:

- 3D CNC measuring devices

- 3D CNC gear measurement

- Surface roughness testers

- Contour measuring devices

- Visual wavemeters

- Digital measuring projectors

- Micro hardness testers (including sample preparation laboratory)

- Tensile and pressure testing devices

- DHS image measuring microscopes

- Surface inspection Fischer X-ray

- Clean room including analytical instruments according to VDA19

- Automated inspection devices (100% optical / tactile)

for project-oriented serial testing.

VARIOUS CUSTOMERS – ONE GOAL

The partnership with our regular customers goes back decades.

We supply both, well-known automotive-Tier-1 customers and customers from non-automotive sectors.

However, all of our customers have one thing in common: high expectations concerning the quality of the products and services as well as the reliability which characterises a partnership.

When evaluating new projects, the industry becomes the secondary aspect since the potential of the customer, the product, and the requirement to build a long-term, trusting partnership are essential to us.

PROFESSIONAL COOPERATION INSTEAD OF SHADY PROCESSES

We are using reliable partners for processes in which we do not see our core competencies.

Long-term partnerships with suppliers and service providers with cutting edge technology are as follows:

- Surface treatment

- Barrel and rack (any common process)

- Thermal processing

- Quenching and tempering (any common hardening techniques)

Appropriate selection processes, release and monitoring procedures in accordance with common specifications (CQI, HTSA, VDA6.3 audit) are key components of management regarding outsourced processes.

A transparent presentation of the entire process chain should go without saying, and assure you that your product will be handled with utmost care.

ANY AMOUNT CAN SHOW GREAT EFFECT

In addition to our automated and optimized mass-production processes, we are experienced in sample manufacturing, prototype, and small-scale production.

Whether design prototype or customer service requirement, we implement parts availability in series quality.

Ready-to-install delivery with inspection report and 100% measuring enables a smooth and documented implementation of your project schedule.